The Canadian wood pellet sector exists primarily to make better use of forests that are already being harvested. Canadian pellet producers ensure the sustainability of their product by dealing exclusively with reputable fibre suppliers with traceable supply chains to source feedstock. That’s why customers requiring sustainable biomass products have confidence in the Canadian wood pellet sector.

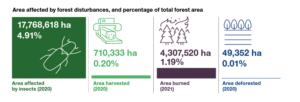

Canada’s forest sector harvests less than one percent of Canada’s commercial forests each year, and of that, less than four percent is used to make pellets. Canada’s forests are some of the most resilient and sustainably managed in the world. They are subject to stringent environmental regulation, careful management, and extensive third-party certification.

Canada has a proven record of sound forest stewardship, with more than 90 percent of its original forest cover remaining and a growing network of protected areas that represent the country’s biological diversity. Forest policies in Canada centre on the concept of sustainable forest management with the underlying goal of achieving a balance between the demands on forests for products and benefits, and the maintenance of forest health and diversity.

Less than one-third of one percent of Canada’s forests are harvested annually and overall Canada’s forests are growing faster than they are being harvested.

Read: Sustainable Forest Management: Strong Regulations and Independent Certification

Canada’s forest industry is highly integrated and maximizes the value of every tree harvested. Canadian wood pellets are produced entirely from sawdust, shavings, harvest residues, and low-quality logs that have been rejected by the other traditional forest sectors—sawmills, pulp mills, and panelboard plants.

A recent study confirms that wood pellets in British Columbia are sourced entirely from sawmill and harvest residuals or from low-quality logs and bush grind rejected by other industries.

Read: Leading Forest Experts Confirm British Columbia Wood Pellets Are Responsibly Sourced

DIVE DEEPER

Fact Sheet

External Link

Stay Current

Sign up for email updates from WPAC